Intro

As our flock has grown, the cost of keeping them fed has also increased. And while we are always on the lookout for "free" food such as vegetables from our garden, left over pumpkins from fall, and any household scraps that they'd enjoy, we still move through about 150 pounds of feed in a week. In the summer months this is reduced since the chickens are usually able to forage for bugs and other tasty morsels. But when winter hits, their feed requirements increase as well.

Additionally, chickens have this cute yet annoying habit of scratching while standing in their bowl. Which leads to feed flying everywhere, and a lot of waste.

The Idea

I've seen this idea all over the place. It's definitely not new. But I figured if it reduced waste it would pay for itself quickly.

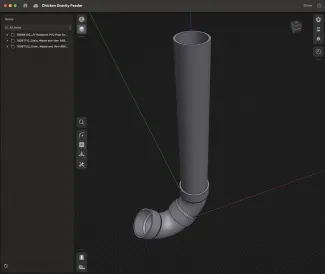

People have been using large diameter irrigation pipe to build gravity feeders. And I think it's genius. That combined with clever 45° and 90° fittings, it makes a nice scoop at the bottom for the feed to fill. Our largest run is where we have the most waste and the most birds. Additionally, we have to keep all of the feed inside since the chickens share the pasture with our goats. And the goats would make quick work of any available chicken feed.

The Design

The design I decided upon is quite simple. Use a three foot length of 3 inch PVC (schedule 40), a 45° fitting, a 90° fitting, and two pipe straps to build a single feeder. Duplicate that two more times and get three feeders for the big run (aka Sparta).

This would allow for storage of some feed in the pipe itself, and gravity would take care of refilling the container. We would mount it off of the ground to prevent the birds from roosting on it, or scratching the feed out onto the ground.

The angled fittings would provide a "slide" for the feed to move through and slow it down enough so it wouldn't all drop out at once. The opening at the end would allow the birds to eat as needed.

Materials

We were originally going to use PVC for this project, but ABS ended up being cheaper. So we used that instead. Our local big-box stores didn't carry 3" pipe at a reasonable price, so we visited our local plumbing warehouse. My dad still has his journeyman plumbing license so we were able to get the materials for all three feeders for about $70. The straps we had to purchase elsewhere and those came up to about $10.

Additional cost would be added for ABS cement, but my dad already had some on hand from plumbing projects.

Assembly

We fitted the pipes together as shown in the diagram above and affixed them to the walls in Sparta, our biggest run. We used a medium sized hen to determine the mounting height to ensure they'd be able to reach the feed comfortably. We had already prepared the way for these feeders by moving our roosting bars to clear up space on one wall in the coops itself.

Once mounted, we filled them up and the birds started using them within minutes.

One thing we noted was for the initial filling, it's a good idea to put your foot or something in the way of the end of the pipe end at the bottom. The first feed to reach the bottom can end up escaping and making a mess. But once they're in, the feed flows naturally down.

What We Learned

- Birds with large combs (like roosters) may have a hard time getting their head into the fitting to eat. Consider cutting of the top of the last fitting to make it more like a "scoop" so the birds can get their heads in there comfortably.

- Pellet feed is best suited for this type of feeder since the grinding of some much feed coming down the tube can tend to break up the feed. Crumble could be pulverized by this method.

- Refilling the pipe really requires a funnel. (I have an idea for that!)

The birds have been using this system for over a month now and they've been doing well! Now to get that issue with the funnel worked out. I'm thinking we can do something with PETG and my 3D printers. 🤔